Production and subsequent processing of cold-rolled metal profiles

With our decades lasting experience with the production and subsequent processing of metal profiles our production facility is specialized in the production of metal goods.

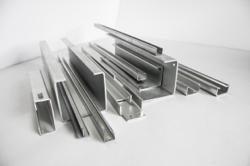

The profile diameters of our standard profiles (u-profiles, c-profiles, l-profiles) can be produced with different measures and without additional tool costs.

- Profile height: max. 100 mm

- Profile width: max. 140 mm

- Tunnel/stock width: 30 - 350 mm

- Material thickness: 0.5 - 3.00 mm

- Profile length: max. 9000 mm

Series production of metal profiles

Our processing lines are well configured for the production of metal profile series. Please have a look at our picture galleries or our short video clips and get an impression of our production.

The cold-rolled profiles are cut with a clipping blade to their exact length. It is a so-called flying-knife unit. While the profile goes uninterrupted ahead the knife has to follow exactly the profile’s movement. After the cut the cutting unit goes back to its initial position and is ready for the next profile to cut.

The profile goes through two stations of the profiling unit. One can see horizontal rolls on the sides that shape the profile’s outline to the desired measures. Further, one can have a look at the diagonal rolls that dive into the profile to reach precise inside radiuses.

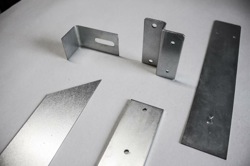

Single-item metal profiles as a sample item or for specific use

Apart from series production of profiles for example for solid wood plates we also produce for short run orders, sample items or single pieces. Depending on the stock width we produce our standard profiles starting with a minimum purchase of 1,5t.